Water management

Neo-Solutions uses a consultative approach to solve Water Management challenges, enabling us to work successfully with management, engineering, operations, outside consultants, and contractors. Our skilled field sales engineers are experienced with finding solutions for all types of Industrial, Municipal, Mining, Quarry, and Industrial Sand applications.

INDUSTRIAL WATER MANAGEMENT APPLICATIONS

Industrial customers are challenged to conserve and recycle water resources, conform to regulatory permitting requirements, and eliminate potential environmental impacts from facility effluent.

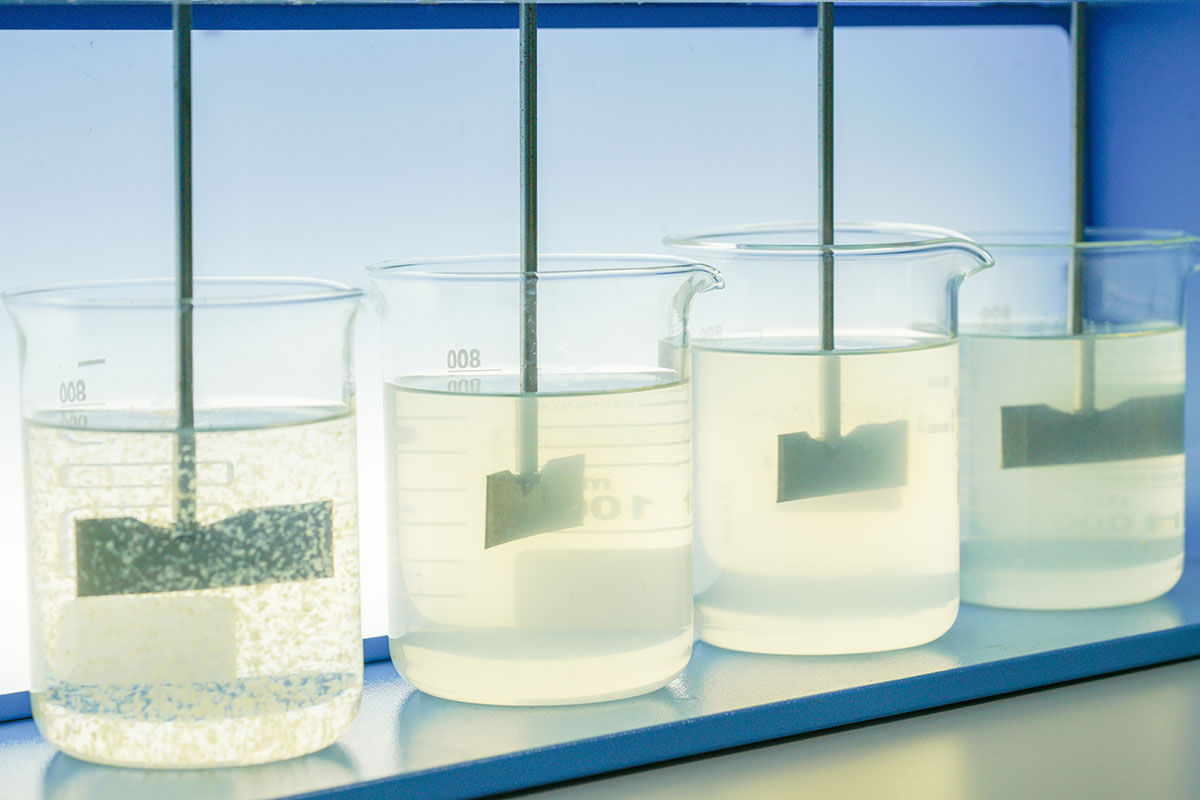

Clarification, Sludge Dewatering & Thickening

Removing precipitate, particulate, and other solids from a process or wastewater stream, as well as dewatering the resulting solids, often presents unique challenges. Industry uses a host of solid/liquid separation unit processes for this purpose, including:

- Clarifiers, Thickeners, Ponds & Settling Basins

- Dissolved Air Flotation Units (DAFs), Filters & Presses

- Centrifuges & Gravity Belt Thickeners

Neo-Solutions has one of the industry’s broadest and most diverse lines of flocculants, coagulants, and dewatering aids. Such variety enables our skilled field sales engineers to rapidly find cost-effective solutions for our customers’ specific processing equipment and water stream requirements.

Scale, Corrosion, Defoaming & Solidification Solutions

- Our Specialty Scale & Corrosion Control Products help to minimize maintenance and infrastructure loss.

- Our Antifoam & Defoaming Products optimize process flows and eliminate environmental issues associated with foaming.

- Our Superabsorbent Products (SAP) are used to “solidify” (by complexing free water) waste material for hauling & disposal.

Difficult-to-Remove Contaminants

Various metals and inorganic contaminants, often found in industrial water streams, present unique challenges to meeting effluent water regulatory requirements. These contaminants include:

- Metals such as cadmium, chromium, copper, lead, manganese, mercury, silver, tin, vanadium, and zinc.

- Semi-metals such as antimony and arsenic.

- Non-metals such as phosphorous and selenium.

Neo-Solutions has developed proprietary product offerings for precipitation and chelation that deliver field proven performance in removing dissolved contaminants. Operations that have soluble metals reduction requirements could likely benefit from utilizing Neo-Solutions’ chemistries and its experienced technical specialists.

We apply innovative solutions to the challenges of many industries and processes, including:

- Meat & Food Processing

- Truck Washing Stations

- Dye Fixatives

- Dredging Lagoons, Catch Basins & Canals

- Metal Finishing

- Powder Coating

- Electronics

- Plastics

- Ferrous & Non-Ferrous Metals Production

- E-coating

- Landfill Leachate Treatment

- Ink & Dye Facilities

- Pulp & Paper

Municipal Drinking Water Management

Society depends upon municipalities and water supply companies to provide safe, clean drinking water. The Neo-Solutions team is focused on helping our customers meet that expectation by using our complete line of NSF/ANSI 60 approved products.

Neo-Solutions products are used to:

- Improve settling & sand filter efficiencies

- Enhance sand filtration

- Reduce turbidity

- Promote backwash capture& solids dewatering

- Eliminate corrosion and scale in infrastructure, piping & equipment

- Optimize sludge generation & characteristics for easy removal

- Decrease backwash cycles

Our application strategies optimize the performance of our chemicals by delivering optimum drinking water quality and improving the efficiencies of water treatment plants and distribution systems. We deliver results using our experience and a complete line of specialty products including coagulants, flocculants, and corrosion and scale inhibitors.

Municipal Wastewater Management

Continually Evolving to Help Customers Meet Municipal Wastewater Challenges

Major operational challenges are the result of industrial expansion, flow rate increases from population growth, and regulatory requirements to lower the limits of constituents in final effluents.

Operational Challenges Require New Solutions

The products and services we offer for sludge-related applications include

- Drier Sludge Cake

- Lower Cost per Ton of Waste Solids Treated

- Improved Mixed Liquor Suspended Solids (MLSS) Settling

- Sludge & Waste-Activated Sludge (WAS) Thickening

- Metals Contaminants Removal

- Pre-Treatment

- Filamentous Outbreaks

- Bacteria Enhancement

- Foam Control

- Scale & Deposit Control

- Reducing BOD (Biological Oxygen Demand)

- Reducing COD (Chemical Oxygen Demand)

- Reducing TDS (Total Dissolved Solids)

- Reducing TSS (Total Suspended Solids)

- Removing FOG (Fats, Oils & Grease)

- Phosphorous Reduction

- Hydrogen Sulfide (H2S) Gas & Odor Prevention, Reduction, or Elimination

- Odor Neutralizers to Hide Non-Harmful Odors

At Neo-Solutions, we collaborate with our customers to optimize their operations. We understand that product selection includes identifying the best performing product that works over the broadest range of dosages and sludge conditions.

Our line of biological control and enhancement products assists with reducing odor generation, as well as keeping bacteria healthy. We have proven products that target and eliminate hydrogen sulfide gas.

Additionally, we supply one of the industry’s largest and most diverse selection of flocculants and coagulants. This competitive advantage sets us apart in sludge settling and dewatering applications. Based on laboratory testing, our technical service engineers identify products providing optimum process stability while delivering excellent cake solids and filtrate quality.

.jpg)

Polymer Performance Impacts Equipment Solids/Liquids Separation Efficiency

Our polymer line is used to optimize the performance of a wide range of equipment including:

- Anaerobic, Aerobic & ATAD Digestion Systems

- Dissolved Air Flotation (DAF) Units

- Plate & Frame Presses

- Rotary Drum Thickeners

- Rotary Fan Presses

- Centrifuges

- Screw Presses

- Clarifiers

- Screw Thickeners

- Trickling Filters

- Deep Cone Thickeners

- Reaction Tanks

- Settling Ponds & Lagoons

- Polymer Make-Down Systems

- External & In-Line Mixing Systems

- Belt Presses, Gravity Belt Thickeners & Screen Bowls

Belt Cleaning Solutions

Filter media cleaners can have a significant impact on operational efficiency by providing these benefits:

- Increased Throughput

- Drier Filter Cake Solids

- Increased Filter Media Life

- Less Filter Blinding

Our belt cleaning products have been shown to deliver an exceedingly high return on investment (ROI). It is not uncommon to achieve 2-3% higher cake solids at minimal cost.

Solving Sludge Handling Issues with Solidification Aids

There are times when operations experience deviations resulting in sludges that cannot be dried sufficiently for handling or transportation. Neo-Solutions’ line of sludge stiffeners (solidification aids) are frequently used to improve the handling characteristics of wetter sludge material by complexing the moisture. This process yields a transformed sludge with no free liquids and improves handling and transport characteristics.

Mining Mineral Processing Water Management

Water is a Precious Resource in Mineral Processing

A typical mineral processing operation may recycle more than 90% of its process water. Any unnecessary water losses to product, dust control, or final effluent will require usage of make-up water which can be scarce or expensive. When chemicals (e.g., collectors, frothers) are added in the beneficiation phase, they can further complicate water management challenges.

Neo-Solutions’ team of water management experts includes professionals with over 40 years of experience managing water in mining environments. We bring this experience, along with our proven portfolio of products to your site so you can meet the most difficult challenges.

Neo-Solutions is SKILLED IN BOTH THE ART AND SCIENCE™ of mining, including:

- Industrial Minerals Sand Mining

- Sand & Gravel

- Proppant (Frac) Sand

- Quarry Operations (Granite, Marble)

- Soft Rock (Coal)

- Acid Mine Drainage Remediation

- Oxides, Carbonates & Silicates

- Hard Rock (Iron Ore, Sulfide Ore)

Thickener, Clarifier & Remote Area Operations

Performance of thickener and clarifier operations is essential to providing clean process water. Our full line of coagulants and flocculants allows our customers to achieve their goals and offers these advantages:

- Excellent water clarity for re-use or final discharge

- Proper underflow density

- Fast settling rates for high thickener and clarifier efficiency

- Stable floc characteristics to resist breakdown & solids losses

- Reduction or elimination of floc carryover

Our flocculant tablets and polymer gel blocks are used in remote areas, ponds, and lagoons, as well as in soil erosion and runoff situations. They require no equipment and are ready-to-use solutions.

Foaming Problems Negatively Impact Operations

Undesirable foaming may be the result of water contaminants leading to:

- Poor Process Efficiency

- Loss of Recovery

- Difficulty with Flow Rates & Pumping

- Spillage from Weirs, Launders & Clarifiers

- Safety Issues

Using our application expertise and our proven line of antifoam and defoamer products enables our customers to control foam-related issues.

Dewatering Applications are Essential to Operations

Proper dewatering of solids is important to conserve water while achieving low transportation costs, good handling characteristics, and/or meeting necessary remediation requirements.

Neo-Solutions has developed a proprietary line of filter (dewatering) aids that lower operating costs and deliver target filter cake moistures.

Applications Benefiting From Dewatering Aids

- Dewatering screens, including ones that reduce product moisture

- Weeping to reduce product moisture & drying time

- Plate & frame filter presses & pressure filters to reduce final cake moisture, improve tons per cycle, reduce cycle times & increase filter media life

- Vacuum filters, such as vacuum belt, rotary disc, rotary drum, and pan filters to reduce moisture, improve productivity, reduce media blinding & increase filter cloth life

- Belt filter presses for increased throughput, drier cake yield, improved cake handling, decreased belt blinding & reduced chemical usage

- Equipment used to dewater tailings for “dry stacking” & tailings rheology management

- Equipment-less alternatives to “dry stack,” sometimes called “mud stacking”

Solidification

Neo-Solutions’ stiffening (solidification) products can be used when the actual percentage of moisture is not critical, yet the tailings or product materials need to handle as though they are drier. These specialized Neo-Solutions products improve handling for transport or material placement.

Equipment Freeze Control Applications

During cold weather, our freeze control product line and custom feed equipment help to start equipment easily, keep switches working, belts running without slipping, and hauling equipment releasing their loads.

Feed Equipment Capability

Neo-Solutions works collaboratively with best-in-class suppliers of feed systems, controls, and automation equipment to optimize products' cost performance, including simple solution feed systems, emulsion feed systems, and dry flocculant feed systems. We work with your chosen equipment supplier, or with one of our partners to meet your requirements. Through our equipment network, we can also provide our customers with support for turbidity and density management strategies.

Our Employees Make a Difference

Delivering Solutions that Achieve the Best Results

Our employees are driven to solve our customers problems and help them deliver on their production and financial commitments. We leverage all our expertise in polymeric and other chemical sciences to solve customer problems for applications in a host of environments, including steel, chemical, food, and other water intensive industrial settings.

Our staff of experienced industry experts, chemical engineers, and chemists are knowledgeable about operational processes and equipment provide:

- On-site service and technical support included with our product offerings

- On-site full trial support, including prior to trial training as required

- Collaboration with our customers to achieve the best results

Our innovative approaches to chemical treatment strategies have been successfully adapted by our customers, generating several "industry firsts".

Our team members' flocculation and coagulation expertise supports our customer requirements by:

- Establishing control parameters for high turbidity in clarifiers

- Selecting the proper chemicals for reduction of suspended solids

- Enhancing the performance and optimization of your processes

Our team prides itself in always striving to exceed our customers' expectation. We welcome the opportunity to solve your most challenging issues and to servicing your needs.